January 28th, 2026 - Zed van der Vyver

The Ultimate Guide to Concrete in Thailand: Building a Foundation That Lasts

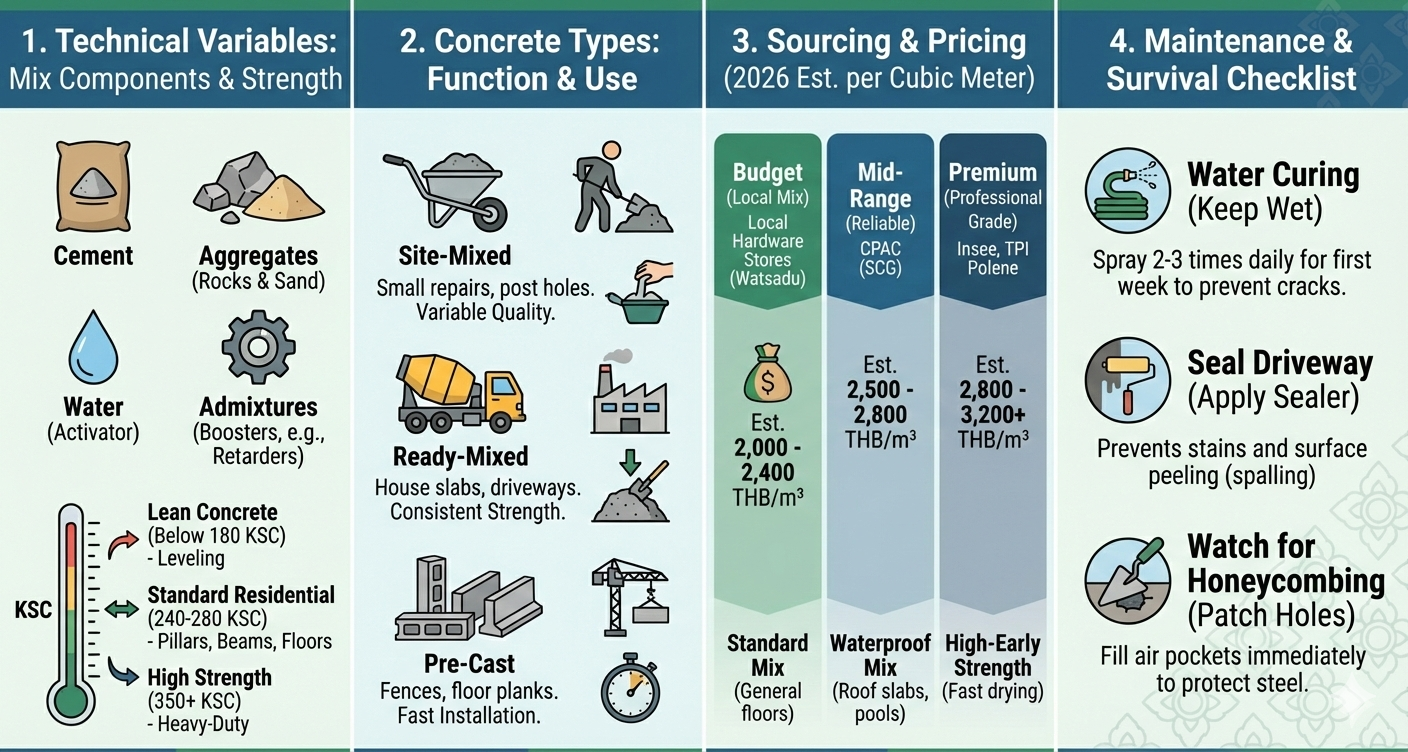

If you are building a house, pouring a driveway, or adding a patio in Thailand, you are going to spend a lot of time thinking about concrete. In the construction world, concrete is the "bread and butter"—it is the most common building material in the country because it is strong, relatively cheap, and can handle the tropical humidity.

Think of concrete like baking a giant cake. If you get the recipe wrong, the cake will crack or collapse. In Thailand’s heat, the "baking" process (called curing) happens fast, and if you aren't prepared, you’ll end up with a dusty, cracked mess.

1. The Technical Breakdown: Understanding the "Moving Parts"

Concrete isn't just one material; it’s a mixture. Understanding the variables helps you ensure your contractor isn't cutting corners.

The Mix Components: The Ingredients

-

Cement: The glue that holds everything together. In Thailand, you’ll mostly see "Portland Cement."

-

Aggregates (Rocks & Sand): These provide the bulk and strength. Think of these as the "flour" in your cake.

-

Water: Activates the cement. Warning: Too much water makes the concrete easy to pour but weak once it dries.

-

Admixtures: These are "boosters" added to the mix. In Thailand, "Retarders" are common—they slow down the drying time so the concrete doesn't harden too fast in the 35°C sun.

Strength Ratings: The "KSC" Scale

In Thailand, concrete strength is measured in KSC (Kilograms per Square Centimeter).

-

Lean Concrete (Below 180 KSC): Used for leveling the ground before the real work starts.

-

Standard Residential (240 – 280 KSC): The "sweet spot" for house Pillars, beams, and floors.

-

High Strength (350+ KSC): Used for heavy-duty driveways or high-rise buildings.

The "Why it Matters" Factor: Using a low KSC for a driveway meant for a heavy SUV will result in deep cracks within a year. Always match the strength to the weight it will carry.

2. Concrete Types: Choosing the Right "Recipe"

Depending on your project size, you have two main ways to get your concrete.

| Type | Best Use Case | The "Why it Matters" Factor |

| Site-Mixed | Small repairs, post holes, or remote areas. | Mixed by hand or small machine. Quality can be inconsistent if the "recipe" isn't followed strictly. |

| Ready-Mixed | House slabs, driveways, and structural beams. | Delivered by the iconic "spinning trucks." It is mixed in a factory for perfect consistency and strength. |

| Pre-Cast | Fences, floor planks, and drainage pipes. | These are "Lego blocks" made of concrete. They are poured in a factory and delivered hard, saving you weeks of construction time. |

3. Sourcing & Market Data: Where to Buy in Thailand

You can find concrete supplies in almost every village, but for big structural pours, you want the big names.

Top Suppliers

-

Budget (The Local Mix): Your neighborhood "Watsadu" (Hardware) store. They sell bags of cement and piles of sand/rock for small DIY projects.

-

Reliable Mid-Range: CPAC (SCG). This is the gold standard in Thailand. They have the largest fleet of trucks and very reliable "Ready-Mix" strength standards.

-

Professional Grade: Insee (Siam City Cement) and TPI Polene. These are massive industrial suppliers known for high-performance concrete and specialized additives.

2026 Pricing Tiers (Estimated)

Prices are based on standard 240 KSC strength.

| Quality Tier | Estimated Price (per Cubic Meter) | Best For |

| Standard Mix | ฿2,000 – ฿2,400 | General floors and walkways. |

| Waterproof Mix | ฿2,500 – ฿2,800 | Roof slabs or swimming pool shells. |

| High-Early Strength | ฿2,800 – ฿3,200 | Projects that need to dry fast (e.g., a busy shop floor). |

4. Maintenance & Survival: The "Layman's" Checklist

Concrete seems "set and forget," but in the tropics, it needs a little love to survive the heat and rain.

-

The "Watering" Rule: After pouring new concrete, you must keep it wet! Spray it with a hose 2-3 times a day for the first week. If it dries too fast in the Thai heat, it will crack.

-

Seal Your Driveway: Use a clear "Concrete Sealer" (found at HomePro). This prevents engine oil and rainwater from soaking into the pores and causing stains or "spalling" (surface peeling).

-

Watch for "Honeycombing": When you remove the wooden forms from a pillar, look for holes that look like a beehive. These are air pockets. Have your contractor patch them immediately with "Non-Shrink Grout" to prevent the steel inside from rusting.

5. Summary & Next Steps

Concrete is the backbone of your Thai home. For a simple garden path, a few bags of cement from the local shop will do. However, for anything structural (like a second floor), always order Ready-Mixed concrete from a reputable brand like CPAC or Insee to ensure your "house cake" doesn't crumble.