January 28th, 2026 - Zed van der Vyver

The Ultimate Guide to Home Insulation in Thailand: Keeping the Heat Out

If you’ve ever walked into your home in the afternoon and felt like you were stepping into a preheated oven, you’ve met the "Tropical Heat Trap." In Thailand, your roof and walls absorb the sun’s energy all day, radiating it into your living space long after the sun goes down.

Think of insulation like a styrofoam cooler box for your house. Just as a cooler keeps your drinks icy even in the sun, insulation keeps the cool air from your AC inside and prevents the outside heat from "leaking" in.

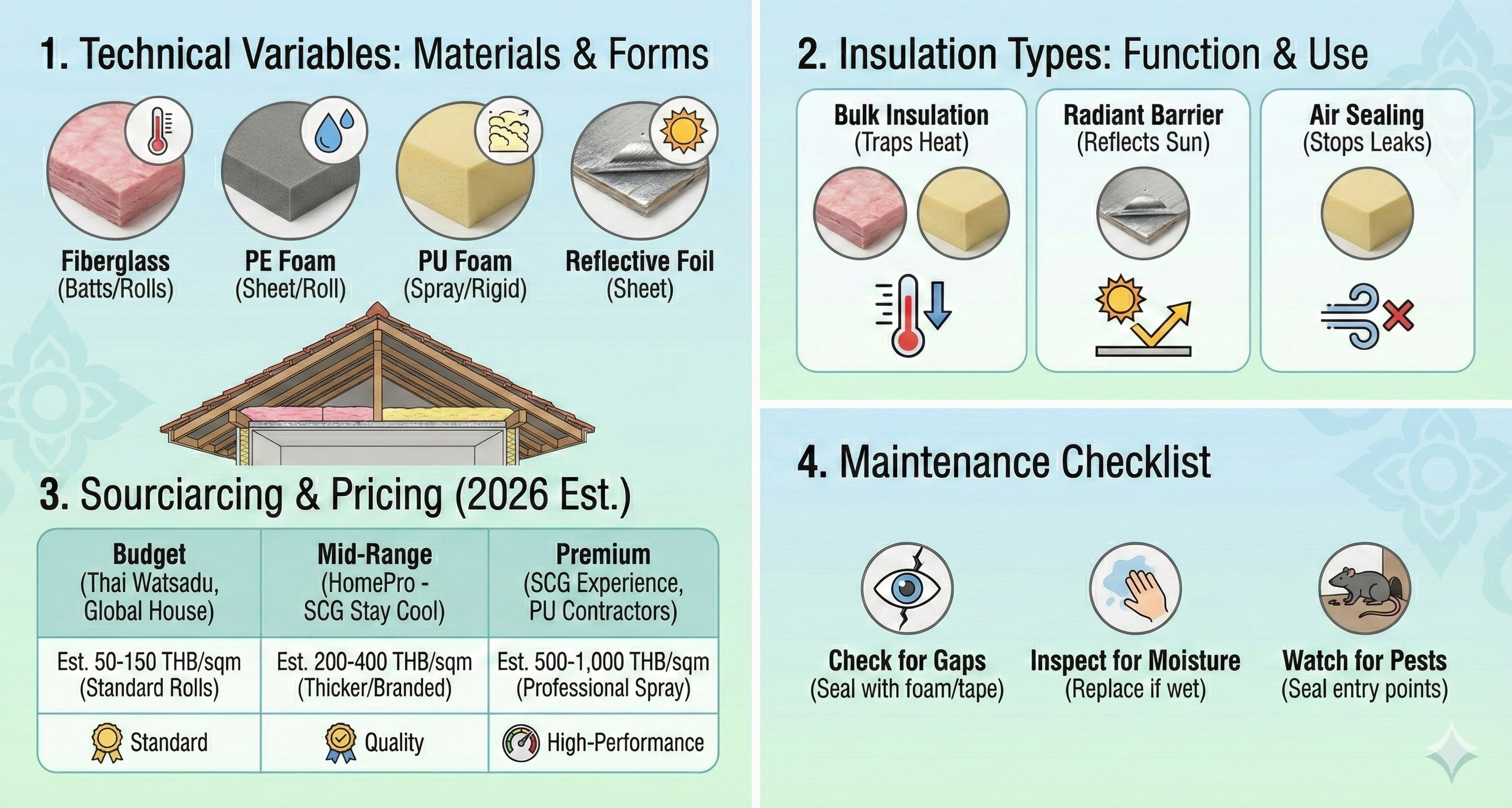

1. The Technical Breakdown: Understanding the "Moving Parts"

Insulation isn't just one product; it’s a system of barriers designed to stop heat in its tracks. To choose the right one, you need to know the variables.

Material Types: The Heat Blockers

-

Fiberglass (Glass Wool): The most popular choice (e.g., SCG Stay Cool). It’s made of recycled glass spun into a fluffy mat and wrapped in aluminum foil.

-

Why it matters: It’s excellent at trapping air, which is a poor conductor of heat. It’s also fire-resistant and doesn't attract bugs.

-

-

PE Foam (Polyethylene): A thin, flexible foam sheet often glued directly to the underside of metal roofs.

-

Why it matters: It’s waterproof and great for preventing "sweating" (condensation), but it offers less heat protection than thick fiberglass.

-

-

PU Foam (Polyurethane): A liquid spray that hardens into a rigid shell.

-

Why it matters: It fills every tiny crack and acts as a glue, strengthening your roof. It's the "gold standard" for sealing, but it's the most expensive and requires professional sprayers.

-

-

Reflective Foil: A thin, shiny sheet installed just under the roof tiles.

-

Why it matters: Think of this as a mirror for heat. It reflects up to 95% of radiant heat back out before it even reaches your ceiling.

-

The Numbers That Count

-

R-Value (Resistance): The higher the number, the better the material is at resisting heat. For a Thai attic, you want at least an R-30 or higher.

-

Thickness: Generally, 3 inches (75mm) is the standard for basic cooling, but 6 inches (150mm) is the "pro move" for 24/7 air-conditioned rooms.

2. Sourcing & Market Data: Where to Buy in Thailand

You can find insulation at almost any major hardware hub in the country. Prices are stable but vary based on thickness.

Top Suppliers

-

Budget (DIY/Standard): Thai Watsadu and Global House. Look for house brands or "Microfiber" rolls. These are perfect for quick attic upgrades.

-

Mid-Range (Reliable Quality): HomePro. They carry the full SCG (Elephant Brand) line, including the "Stay Cool" series, which is the benchmark for residential insulation in Thailand.

-

Premium (Full Systems): SCG Experience or specialized PU Spray Contractors. Best for new builds where you want the insulation integrated into the walls and roof structure from day one.

2026 Pricing Tiers (Estimated)

| Product Type | Estimated Price (THB/Roll or sqm) | Coverage |

| Reflective Foil Sheet | ฿1,200 – ฿2,000 per roll | ~60 sqm |

| Fiberglass (3-inch / 75mm) | ฿300 – ฿450 per roll | ~2.4 sqm |

| Fiberglass (6-inch / 150mm) | ฿550 – ฿800 per roll | ~2.4 sqm |

| PU Foam Spray | ฿400 – ฿700 per sqm | Custom Applied |

Pro Tip: Investing in 6-inch insulation over 3-inch usually pays for itself in electricity savings within 18–24 months if you run your AC daily.

3. Installation: The "Layman's" Strategy

You don’t need to be an engineer to insulate your home. Most Thai homes have a "crawl space" above the ceiling.

-

The "Blanket" Method: Buy rolls of foil-backed fiberglass and simply roll them out over your ceiling boards. Ensure the foil side faces up to reflect the heat coming from the roof.

-

Gap Control: Don't leave spaces between rolls. Heat is like water; it will find the smallest "hole" and pour into your room.

-

Ventilation is Key: Insulation slows down heat, but a roof vent (Eave vents or a "whirlybird" fan) lets the trapped hot air escape. Without vents, your attic becomes a pressurized heat cooker.

4. Maintenance & Safety

-

Watch the Critters: Rats love warm, fluffy insulation. If you hear scratching, fix your roof gaps immediately.

-

Water Damage: If your roof leaks, fiberglass can act like a sponge. If it gets soaked, it loses its "fluffiness" and its ability to stop heat. Always check your insulation after a major monsoon storm.

-

Skin Protection: If you're doing it yourself, wear long sleeves and a mask. Fiberglass is made of tiny glass shards that will make you itch for days!

5. Summary & Next Steps

Insulating your roof is the single most effective way to lower your "Electric Bill Stress" in Thailand. For most homeowners, a weekend spent laying 6-inch SCG Stay Cool rolls in the attic is the best bang-for-your-baht upgrade you can make.